Auger Screw Valves and Controllers

FULL SYSTEM PACKAGE - Valve with Syringe Feed, ServoController and Valve Stand

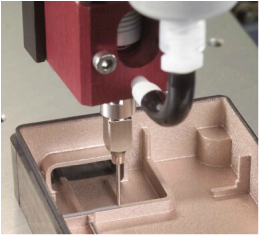

The DPAV-200-PKG is a benchtop or automation capable auger dispensing valve and the 7070000 Servo Valve controller that can connect to a robot with an IO cable or used manually with a foot pedal trigger. This unit is a 7080006 stand-mounted DPAV-200 Servo Driven Auger Valve fed by a 30cc or 55cc pneumatic syringe and includes a sample kit of various needle sizes. It is provided with the 8 pitch unless otherwise requested. Larger reservoirs are available to upgrade. Contact an IDS representative for a quote.

Requires regulated compressed air lines up to 100PSI for each unit to function. 115V or 230V power supply. Intended for high accuracy small dot or line deposits, even if the material thickens over time or changes in thickness from batch to batch. Perfect for Solder Paste, flux, and other filled materials.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility. Minimum material viscosity: 25,000cps

|

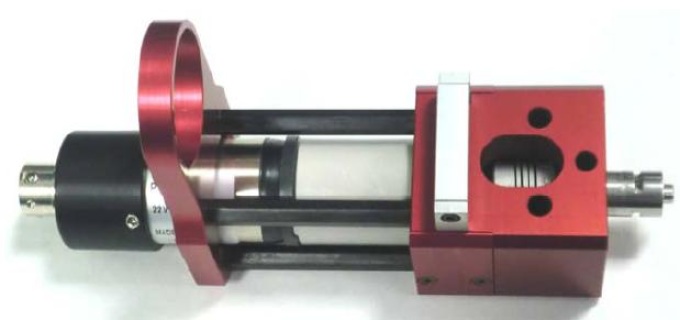

The IntelliSpense Screw Controller (shown above) will both regulate the air pressure to keep the fluid feeding into the valve and make it possible to adjust the time needed to dispense the shot size required.

When the system is triggered either by the foot pedal or an external signal (DB9), the valve motor and the feed air to the syringe are activated. The amount of time that the valve is on and the voltage on the servo motor depends upon the timer settings and whether the unit is in auto, manual or teach mode. At the end of the dispense sequence, the feed air shuts off and the motor reverses direction for a set amount of time, which is also adjustable. IDS suggests purchasing the material pre-packaged in a pneumatic syringe from the formulator when possible. Filling syringes with thick material can be difficult in house, and air bubbles can get trapped in the syringe without a de-gassing step that professional packagers will use. |

Auger Valves are excellent for medium to thick, filled materials suitable for medium to high viscosity pastes, epoxies, filled materials. Solder Paste and Conductive Paste. Difficult to clean material? The Auger separates easily from the body to clean and replace, without tools, in seconds. They can easily be mounted on an IntelliSpense Robot or used as a stand-alone work station, with a stand or a gun.

Features

|

Specifications

- Motor voltage: 24VDC servo motor

- maximum inlet fluid pressure: 100 PSI

- Auger material: stainless steel

- Minimum material viscosity: 25,000cps

- Minimum shot size: 0.020" (0.508mm)

- Dimensions: 139.70 mm to 69.22 mm x 29.21 mm

- Weight: 9 oz (255gm)

System Components and Rebuild Kits:

The DPAV-200 Auger Screw Valve is a manual controlbenchtop or automation capable auger dispensing valve. It is the newest design of the 7060000 series of the valve we have offered for many years. Specify the desired Syringe Feed size and auger screw pitch when ordering.

Requires regulated compressed air lines up to 100PSI for each unit to function, as well as our 7070000 Auger Valve Controller. The Valve Stand is also suggested. 115V or 230V power supply. Intended for high accuracy small dot or line deposits, even if the material thickens over time or changes in thickness from batch to batch. Perfect for Solder Paste and other filled materials.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility. Minimum material viscosity: 25,000cps

Requires regulated compressed air lines up to 100PSI for each unit to function, The Valve Stand is also suggested along with the valve. 115V or 230V power supply.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility.

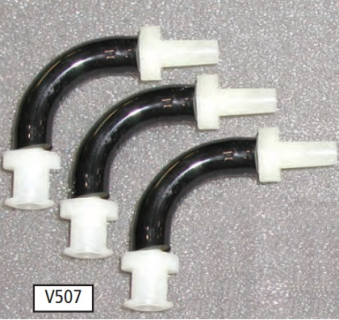

V507 Feed tubes only. Bag of 10

Intended for use with our DPAV-200 auger screw valve or older 7060000 series auger screw valves only. Not Intended For Use With Any Other IDS Valves.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility.