Dispensing Valves, Controllers and Accessories

7020000 = Manual Diaphragm Valve ONLY

VALVE ONLY

The 7020000 - Manual Diaphragm Valve is intended to be used with any pressurized reservoir. NO VALVE CONTROLLER REQUIRED.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 20,000 cps

7040000-3 = Auto Diaphragm Valve ONLY

The 7040000 - Automatic Diaphragm Valve is intended to be used with any pressurized reservoir. Requires a valve controller that can provide air pressure to close.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

5101292 = Front Closing Valve ONLY

VALVE ONLY

The 5101292 = Front Closing Valve is intended to be used with any pressurized reservoir. Requires a valve controller that can provide air pressure to open and close. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: Depends on Reservoir, used for all viscosity 1 cps - Paste cps.

5101292-MIC = Front Closing, high pressure valve with Micrometer

The 5101292-MIC = Front Closing, high pressure valve with Micrometer is intended for use with low to high viscosity materials, for single component bead, dot, potting, or encapsulation projects. The micrometer flow adjustment makes fine tuning of your process easy to do on the fly. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

You also require a valve controller and reservoir. Contact IDS with questions.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

7052000 = Micro-Mini Metering Valve without Micrometer (0.0015-0.012 cc)

VALVE ONLY

The 7052000 = Micro-Mini Metering Valve without Micrometer (0.0015-0.012 cc) is intended for use with low to medium viscosity materials. You also require a valve controller and reservoir. Contact IDS with questions.

Intended for high accuracy micro dot deposits.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Viscosity Range: Depends On Reservoir - 1 cps - Paste

7053000 = Mini Metering Positive Displacement Valve (0.010 - 0.100 cc)

The 7053000 = Mini Metering Positive Displacement Valve (0.010 - 0.100 cc) is intended for use with low to medium viscosity materials. You also require a valve controller and reservoir. Contact IDS with questions.

Intended for high accuracy micro dot deposits.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

DPAV-200 = Auger Screw Valve With Motor Quick Release Button - VALVE ONLY

The DPAV-200 Auger Screw Valve is a manual controlbenchtop or automation capable auger dispensing valve. It is the newest design of the 7060000 series of the valve we have offered for many years. Specify the desired Syringe Feed size and auger screw pitch when ordering.

Requires regulated compressed air lines up to 100PSI for each unit to function, as well as our 7070000 Auger Valve Controller. The Valve Stand is also suggested. 115V or 230V power supply. Intended for high accuracy small dot or line deposits, even if the material thickens over time or changes in thickness from batch to batch. Perfect for Solder Paste and other filled materials.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility. Minimum material viscosity: 25,000cps

7052250 = Positive Displacement Dispensing Valve ONLY (0.0001 - 0.012 cc)

VALVE ONLY

The 7052250 Positive Displacement Dispensing Valve (0.0001 - 0.012 cc) is intended for use with low to medium viscosity materials. You also require a valve controller and reservoir. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material. Contact IDS with questions.

Intended for high accuracy micro dot deposits. Customer to specify needle gauge size when ordering (See Gauge Chart In Pictures). Customer may request a Luer Lock Adapter instead. Please note choice in "Note to Seller" box at checkout.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Viscosity Range: 1 cps – 50,000 cps

7055000 = 0.1cc to 1.45 cc shot size range Positive Displacement Valve Only

The 7055000 positive displacement valve Is intended for dot deposits or filling applications. Contact an IDS representative for a quote on a full system. Requires 2 regulated compressed air lines, up to 100psi, each to function. Also requires a material reservoir to constantly feed material to the valve

Intended for high accuracy small to large dot deposits, even if the material thickens over time or changes in thickness from batch to batch. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

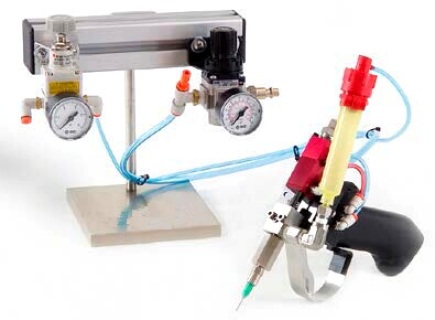

7053000PKG = 0.01cc to 0.1cc shot size range System

FULL SYSTEM PACKAGE - SHIPPING COST INCLUDED IN PRICE - anywhere in the Continental USA via UPS.

The 7053000PKG is a 7080000 pneumatic pistol grip mounted 7053000 positive displacement dispense valve with regulator assembly, fed by a 30CC or 55CC pneumatic syringe. Includes a sample kit of various needle sizes. Requires 2 regulated compressed air lines, up to 100PSI each with tube compression fittings.

The valve is intended for high accuracy small dot deposits, even if the material thickens over time or changes in thickness from batch to batch. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

7020000-2LPKG = 2 Liter Manual Diaphragm Dispense System

FULL SYSTEM PACKAGE

The 7020000-2LPKG includes the 7020000 manual diaphragm valve, material line, the 7011010-2L - 2 liter open top reservoir, and a desktop stand to hold the valve when not in use. Requires clean compressed air up to 100psi. This system is intended for manual user control only, for dispensing low to medium viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 20,000 cps

7020000-5LPKG = 5 Liter Manual Diaphragm Dispense Station

The 7020000-5LPKG includes the 7020000 manual diaphragm valve, material line, the 7011010-5L - 5 liter open top reservoir, and a desktop stand to hold the valve when not in use. Requires clean compressed air up to 100psi. This system is intended for manual user control only, for dispensing low viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

The Augur Valve is the most common valve used in automatic dispensers for electronics assembly, and is best in use with solder pastes or other filled materials. An electric motor drives an augur inside the dispensing chamber. As the augur turns, it brings the material along, out of the chamber. How much material is pushed out depends on how long the motor runs, the viscosity of the adhesive, and the diameter, pitch and depth of the augur. Augur Valves are faster than time-pressure systems, but slower than piston and jetting valves. They can dispense a dot for an 0806 component in 50 to 80 milliseconds. Augur valves dispense a wide range of volumes, and they can handle filled materials.

The Metering Piston Valve is a true positive-displacement applicator. That is, each cycle produces a set volume of material dispensed. The valve consists of a matching piston and cylinder. Adhesive fills the open cylinder from the top. The piston seals the cylinder and forces the adhesive out the bottom. The advantage of piston valves is they compress only the amount of material that you want to dispense and the rest of the material is not stressed. It’s at 2 or 3 psi, which is enough pressure to keep it flowing. Piston valves are least affected by viscosity changes.

The Spray Valve is used for Conformal Coating applications, or to spray any low viscosity material. It is used to apply solvent based conformal coating or UV curable conformal coating epoxy to a circuit board, spray masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux, or paint, and more.

FULL SYSTEM PACKAGE - SHIPPING COST INCLUDED IN PRICE - anywhere in the Continental USA via UPS.

The 7053000PKG is a 7080000 pneumatic pistol grip mounted 7053000 positive displacement dispense valve with regulator assembly, fed by a 30CC or 55CC pneumatic syringe. Includes a sample kit of various needle sizes. Requires 2 regulated compressed air lines, up to 100PSI each with tube compression fittings.

The valve is intended for high accuracy small dot deposits, even if the material thickens over time or changes in thickness from batch to batch. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

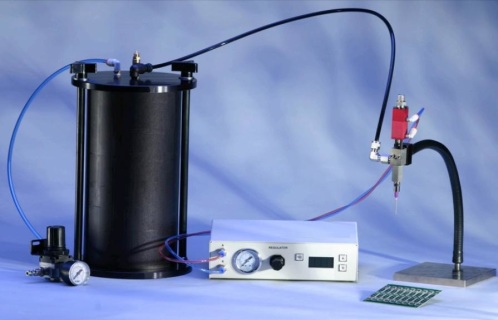

FULL SYSTEM PACKAGE

The 7020000-2LPKG includes the 7020000 manual diaphragm valve, material line, the 7011010-2L - 2 liter open top reservoir, and a desktop stand to hold the valve when not in use. Requires clean compressed air up to 100psi. This system is intended for manual user control only, for dispensing low to medium viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 20,000 cps

The 7020000-5LPKG includes the 7020000 manual diaphragm valve, material line, the 7011010-5L - 5 liter open top reservoir, and a desktop stand to hold the valve when not in use. Requires clean compressed air up to 100psi. This system is intended for manual user control only, for dispensing low viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

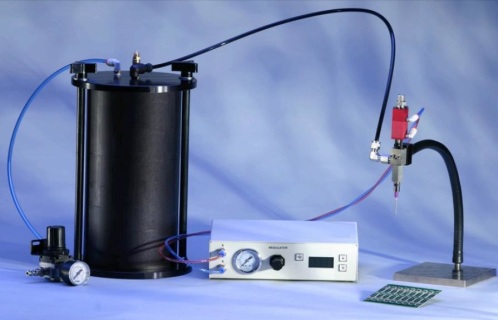

FULL SYSTEM PACKAGE

The 7040000-3-2LPKG includes the 7040000-3 Automatic Diaphragm Valvethe 7011010-2L - 2 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi. This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for dispensing low viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps

FULL SYSTEM PACKAGE

The 7040000-3-2LPKG includes the 7040000-3 Automatic Diaphragm Valvethe 7011010-5L - 5 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi. This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for dispensing low viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps

The 5101292-2LPKG includes the 5101292 Front Closing Valve the 7011010-2L - 2 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi.

This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for potting and encapsulation for electronics and medical device, Filling molds, timed dispensed shots filling vials or other receptacles, epoxy dispensing, flux, dam and fill, Paints and more. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

FULL SYSTEM PACKAGE

The 5101292-5LPKG includes the 5101292 Front Closing Valve the 7011010-5L - 5 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi.

This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for potting and encapsulation for electronics and medical device, Filling molds, timed dispensed shots filling vials or other receptacles, epoxy dispensing, flux, dam and fill, Paints and more. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps

Full Station With 30/55cc Syringe Reservoir

The 7052250 Positive Displacement Dispensing Valve (0.0001 - 0.012 cc) is intended for use with low to medium viscosity materials. The 7052250PKG full system package includes: a 5900011VC valve controller with foot pedal trigger and DB9 port, the 7052250 valve and 7080006 valve stand and 7011010-Ssyringe adapter reservoir.These valves are steel and are not suggested for use with CA (Cyanoacrylate) material. Contact IDS with questions, and always double check your compatability.

Intended for high accuracy micro dot deposits. Not intended for drawing lines.

Valve includes a reusable precision tip. Customer to specify required needle gauge size when ordering (See chart in photographs). Customer may request a Luer Lock adapter, if they prefer. Please include your choice in the "Note to Seller" box at checkout, or contact IDS directly.

.Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Viscosity Range: 1 cps – 50,000 cps

The 7055000DAK is a desk top or automation system which includes the pneumatic pistol grip controller to be used manually. Trigger cycles the valve to dispense manually adjusted set volume between 0.1cc to 1.45 cc . This Item Will Require A Tool Balance - approximate weight is 6 pounds. Tool balance not provided. The gun does have a mounted ring to attach to your tool balance.

* 7055000 Positive displacement metering valve, (volume per cycle 0.10 – 1.45cc)

* 7080000 Pneumatic trigger handle to mount & activate valve

* Direct Syringe Mount, 30cc Universal syringe air adapter, luer fluid connection, air regulator & gauge assy., etc.

Contact an IDS representative with questiond. Requires 2 regulated compressed air lines, up to 100psi, with tube fittings. 115V or 230V power supply.

Intended for high accuracy small to large dot deposits, even if the material thickens over time or changes in thickness from batch to batch. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: Can range from 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

The 7055000 positive displacement valve Is intended for dot deposits or filling applications. Contact an IDS representative for a quote on a full system. Requires 2 regulated compressed air lines, up to 100psi, each to function. Also requires a material reservoir to constantly feed material to the valve

Intended for high accuracy small to large dot deposits, even if the material thickens over time or changes in thickness from batch to batch. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

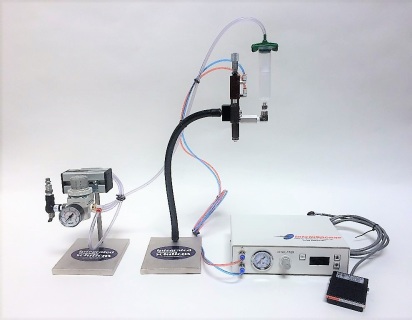

FULL SYSTEM PACKAGE - Valve with Syringe Feed, ServoController and Valve Stand

The DPAV-200-PKG is a benchtop or automation capable auger dispensing valve and the 7070000 Servo Valve controller that can connect to a robot with an IO cable or used manually with a foot pedal trigger. This unit is a 7080006 stand-mounted DPAV-200 Servo Driven Auger Valve fed by a 30cc or 55cc pneumatic syringe and includes a sample kit of various needle sizes. It is provided with the 8 pitch unless otherwise requested. Larger reservoirs are available to upgrade. Contact an IDS representative for a quote.

Requires regulated compressed air lines up to 100PSI for each unit to function. 115V or 230V power supply. Intended for high accuracy small dot or line deposits, even if the material thickens over time or changes in thickness from batch to batch. Perfect for Solder Paste, flux, and other filled materials.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility. Minimum material viscosity: 25,000cps

FULL SYSTEM PACKAGE - Specify round or flat spray cap when ordering.

The 5900011-5LT-PKG is a pistol grip mounted system which includes the 5900011R spray valve (round cap) unless otherwise specified. It is intended to be used manually. The pneumatic trigger handle to mount & activate valve uses 0-15psi and includes the atomizing air regulator with gauge assembly. The system uses the 7011010-L, 5-Liter bottle pressure tank assembly with air regulator & gauge. All fluid & air fittings & tubing to complete connections within system. Stand for valve & trigger handle while not in use.

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Larger reservoirs are available. Contact an IDS representative for a quote. Requires regulated compressed air lines, up to 100psi. No electrical connection required.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Need this system automated? We can provide you with a quote for that. Contact IDS directly. This system is not intended for automation.

|

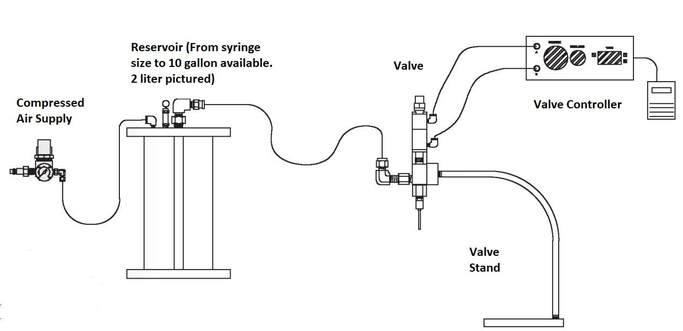

System Components:

Please be sure that you have everything you need when ordering individual components. Contact an IDS representative with questions at any time! |