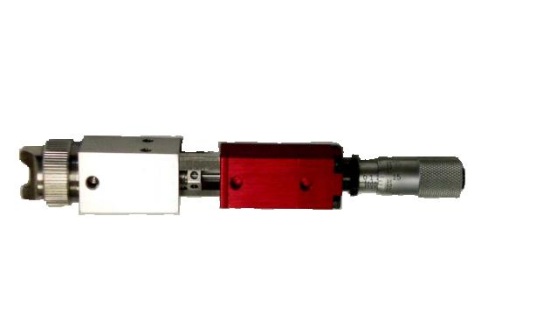

5900011 Spray Valve

The 5900011 Spray valve series provides a repeatable, concentrated coating film in pattern widths ranging from 0.25” to over 2”. The atomized spray process will produce conical (round cap) or fan-shaped (flat cap) patterns with transfer efficiencies in excess of 99%. The most current design features a micrometer flow adjustment that makes fine tuning of your process easier than ever.

The lower air chamber in the valve, moved by air pressure, forces the needle to retract, just as it does in a front closing valve. While the needle is lifted,fluid flows through the spray head. Simultaneously, as the needle is lifted, air enters the chamber, atomizing the fluid. Once the cycle finishes, air pressure is diverted from the lower half of the valve to the upper. This forces the movable plate behind the needle to force it back down and seat it, assisted by the spring, assuring a sharp cutoff of fluid and air. In summary, spray may be fine tuned by turning the adjustment knob. Material deposit and flow rate are controlled by fluid pressure, needle stroke, distance from the valve to work surface and the duration that the valve is opened.

The lower air chamber in the valve, moved by air pressure, forces the needle to retract, just as it does in a front closing valve. While the needle is lifted,fluid flows through the spray head. Simultaneously, as the needle is lifted, air enters the chamber, atomizing the fluid. Once the cycle finishes, air pressure is diverted from the lower half of the valve to the upper. This forces the movable plate behind the needle to force it back down and seat it, assisted by the spring, assuring a sharp cutoff of fluid and air. In summary, spray may be fine tuned by turning the adjustment knob. Material deposit and flow rate are controlled by fluid pressure, needle stroke, distance from the valve to work surface and the duration that the valve is opened.

|

Atomizing Spray Valve Design Features

|

Atomizing Spray Valve Specifications

|

5900011-5LT-PKG = Manual Conformal Coating Spray System

$

5,560.00

SHIPPING COST INCLUDED IN PRICE - anywhere in the Continental USA that can receive UPS Ground shipments.

FULL SYSTEM PACKAGE - Specify round or flat spray cap when ordering.

The 5900011-5LT-PKG is a pistol grip mounted system which includes the 5900011R spray valve (round cap) unless otherwise specified. It is intended to be used manually. The pneumatic trigger handle to mount & activate valve uses 0-15psi and includes the atomizing air regulator with gauge assembly. The system uses the 7011010-L, 5-Liter bottle pressure tank assembly with air regulator & gauge. All fluid & air fittings & tubing to complete connections within system. Stand for valve & trigger handle while not in use.

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Larger reservoirs are available. Contact an IDS representative for a quote. Requires regulated compressed air lines, up to 100psi. No electrical connection required.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Need this system automated? We can provide you with a quote for that. Contact IDS directly. This system is not intended for automation.

FULL SYSTEM PACKAGE - Specify round or flat spray cap when ordering.

The 5900011-5LT-PKG is a pistol grip mounted system which includes the 5900011R spray valve (round cap) unless otherwise specified. It is intended to be used manually. The pneumatic trigger handle to mount & activate valve uses 0-15psi and includes the atomizing air regulator with gauge assembly. The system uses the 7011010-L, 5-Liter bottle pressure tank assembly with air regulator & gauge. All fluid & air fittings & tubing to complete connections within system. Stand for valve & trigger handle while not in use.

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Larger reservoirs are available. Contact an IDS representative for a quote. Requires regulated compressed air lines, up to 100psi. No electrical connection required.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Need this system automated? We can provide you with a quote for that. Contact IDS directly. This system is not intended for automation.

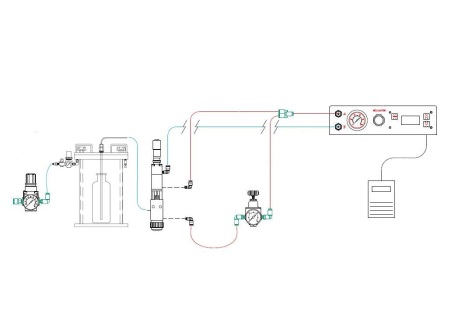

5900011-2LT-DSKPKG = Spray Valve System For Desktop Use or Automation

$

5,980.00

SHIPPING COST INCLUDED IN PRICE - anywhere in the Continental USA that can receive UPS Ground shipments.

FULL SYSTEM PACKAGE - Specify round or flat spray cap when ordering.

Includes the 5900011 spray valve (Specify Round or Flat Cap), the 5900011SVC11 digital valve controller with foot pedal activation and 0-15psi atomizing air regulator with gauge assembly, 7080006 Adjustable Valve Stand, and the 7011010-2L 2 Liter Reservoir, also includes regulator stand assembly and all necessary fluid & air, fittings & tubing within system.

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Larger reservoirs are available. Contact an IDS representative for a quote. Requires regulated compressed air lines, up to 100psi. No electrical connection required.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Need this system automated? We can provide you with a quote for that. Contact IDS directly. This system is not intended for automation.

FULL SYSTEM PACKAGE - Specify round or flat spray cap when ordering.

Includes the 5900011 spray valve (Specify Round or Flat Cap), the 5900011SVC11 digital valve controller with foot pedal activation and 0-15psi atomizing air regulator with gauge assembly, 7080006 Adjustable Valve Stand, and the 7011010-2L 2 Liter Reservoir, also includes regulator stand assembly and all necessary fluid & air, fittings & tubing within system.

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Larger reservoirs are available. Contact an IDS representative for a quote. Requires regulated compressed air lines, up to 100psi. No electrical connection required.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Need this system automated? We can provide you with a quote for that. Contact IDS directly. This system is not intended for automation.

5900011R = Spray Valve - Round Spray Cap

$

2,740.00

VALVE ONLY - Does not include controller or reservoir

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

5900011F = Spray Valve - Flat Spray Cap

$

2,740.00

VALVE ONLY - Does not include controller or reservoir

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.

Use to spray any low viscosity material, apply solvent based conformal coating or UV curable conformal coating to a circuit board, spray a masking material onto turbines before they are chemically treated, spray solvent onto a motor housing to clean and prepare the surface, spray light grease onto a bearing or race during assembly, spray flux.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.