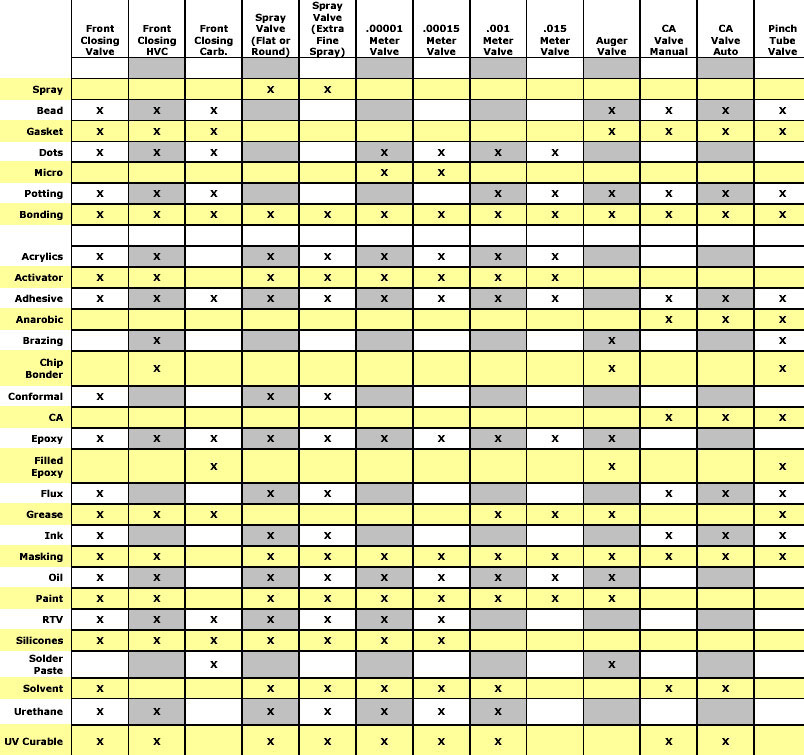

Valve Finder Guide

At IDS, we make your return on investment our highest priority. The first step to understanding your needs is to decide on the formulation. Once you have chose the material to dispense we then need an idea of the individual deposit size in volume, as well as what your throughput will dictate for total usage in a day or in a shift. Will it be CCs, Ounces, or Gallons? Will your desired throughput rates require automation?

IDS valve based systems are often used in Bulk Dispensing applications, but they are also used in high accuracy positive displacement or volumetric dispensing applications that can provide micro dot repeatability and accuracy. For bulk dispensing applications, the volume of usage will determine what the size of the reservoir needs to be. For a typical dispensing valve setup, click here! Of course, not every valve is the same. Some use bulk reservoirs and others are more commonly fed by a syringe.

Still need help? Dispensing is not easy, and there are many options. Contact an IDS representitive today for more information!

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system, be sure to confirm compatibility.

The 7040000 - Automatic Diaphragm Valve is intended to be used with any pressurized reservoir. Requires a valve controller that can provide air pressure to close.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

VALVE ONLY

The 7020000 - Manual Diaphragm Valve is intended to be used with any pressurized reservoir. NO VALVE CONTROLLER REQUIRED.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 20,000 cps

VALVE ONLY

The 7052250 Positive Displacement Dispensing Valve (0.0001 - 0.012 cc) is intended for use with low to medium viscosity materials. You also require a valve controller and reservoir. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material. Contact IDS with questions.

Intended for high accuracy micro dot deposits. Customer to specify needle gauge size when ordering (See Gauge Chart In Pictures). Customer may request a Luer Lock Adapter instead. Please note choice in "Note to Seller" box at checkout.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility. Viscosity Range: 1 cps – 50,000 cps

FULL SYSTEM PACKAGE - SHIPPING COST INCLUDED IN PRICE - anywhere in the Continental USA via UPS.

The 7053000PKG is a 7080000 pneumatic pistol grip mounted 7053000 positive displacement dispense valve with regulator assembly, fed by a 30CC or 55CC pneumatic syringe. Includes a sample kit of various needle sizes. Requires 2 regulated compressed air lines, up to 100PSI each with tube compression fittings.

The valve is intended for high accuracy small dot deposits, even if the material thickens over time or changes in thickness from batch to batch. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

FULL SYSTEM PACKAGE

The 7020000-2LPKG includes the 7020000 manual diaphragm valve, material line, the 7011010-2L - 2 liter open top reservoir, and a desktop stand to hold the valve when not in use. Requires clean compressed air up to 100psi. This system is intended for manual user control only, for dispensing low to medium viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 20,000 cps

FULL SYSTEM PACKAGE

The 7040000-3-2LPKG includes the 7040000-3 Automatic Diaphragm Valvethe 7011010-2L - 2 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi. This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for dispensing low viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps

The 7020000-5LPKG includes the 7020000 manual diaphragm valve, material line, the 7011010-5L - 5 liter open top reservoir, and a desktop stand to hold the valve when not in use. Requires clean compressed air up to 100psi. This system is intended for manual user control only, for dispensing low viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

FULL SYSTEM PACKAGE

The 7040000-3-2LPKG includes the 7040000-3 Automatic Diaphragm Valvethe 7011010-5L - 5 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi. This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for dispensing low viscosity flow-able material. Flux, Cyanoacrylates, Paints and more.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps

FULL SYSTEM PACKAGE - Valve with Syringe Feed, ServoController and Valve Stand

The DPAV-200-PKG is a benchtop or automation capable auger dispensing valve and the 7070000 Servo Valve controller that can connect to a robot with an IO cable or used manually with a foot pedal trigger. This unit is a 7080006 stand-mounted DPAV-200 Servo Driven Auger Valve fed by a 30cc or 55cc pneumatic syringe and includes a sample kit of various needle sizes. It is provided with the 8 pitch unless otherwise requested. Larger reservoirs are available to upgrade. Contact an IDS representative for a quote.

Requires regulated compressed air lines up to 100PSI for each unit to function. 115V or 230V power supply. Intended for high accuracy small dot or line deposits, even if the material thickens over time or changes in thickness from batch to batch. Perfect for Solder Paste, flux, and other filled materials.

Availability: 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to speak with an IDS employee before ordering to confirm the compatibility. Minimum material viscosity: 25,000cps

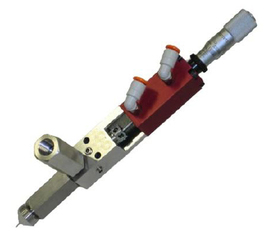

The 7055000 positive displacement valve Is intended for dot deposits or filling applications. Contact an IDS representative for a quote on a full system. Requires 2 regulated compressed air lines, up to 100psi, each to function. Also requires a material reservoir to constantly feed material to the valve

Intended for high accuracy small to large dot deposits, even if the material thickens over time or changes in thickness from batch to batch. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system with your material, be sure to confirm compatibility.