Front Closing Needle Valves

This is an excellent all purpose, single material valve, used in a variety of applications, including beads, gaskets, shots both large and small (including a new design for micro dots) potting and bonding. This valve is also sometimes referred to as a front closing valve, needle valve, high pressure valve, or silicone valve, and is perfect for grease dispensing, lubricant dispensing valve, silicone dispensing.

These valves are steel and do not work well with CA (Cyanoacrylate) material. The steel tends to produce moisture that will cure the CA (Cyanoacrylate) inside the valve. As always, be sure to check with your formulator for material compatibility with any wetted parts or o-rings. If material is gritty, a carbide steel version is available.

A piston-driven needle stops the flow of material when it is in the closed position, resting in a seal, or seat. When an air pulse drives the piston back, it also lifts the needle, allowing material to pass on through the disposable tip to the workpiece. A threaded, adjustable stop regulates the travel distance for the piston. Even though the actual needle is in contact with the material being dispensed, needle valves employ various types of seals, packing and packing nuts to separate the material in the fluid chamber from piston and air cylinders.

Wetted parts are available in either hard-coated aluminum or stainless steel, allowing them to stand up to harsh use. Seals and packing materials can be Teflon, an ultra-high molecular weight plastic or some other material, again depending on the material being dispensed. Some include a carbide ball at the tip of the needle and a hardened seat, to ensure a good seal and increase the life of the valve.

As an added benefit, because the needle shutoff point can be placed at the very end of the valve where it mates with the dispense tip, there is little, if any, dead fluid volume in the valve. This “tip-seal” configuration helps eliminate the problem of dripping of most materials between dispense cycles.

Although the word “needle” might make these types of valves seem like they are small, they are well suited to high-volume applications as well. Needle valves can also be effective when dispensing gels that are sensitive to pressure and shear stress, because they require the material to take a minimum of sharp bends. A lot of needle valves are employed specifically because of their long life and robust delivery of volumes.

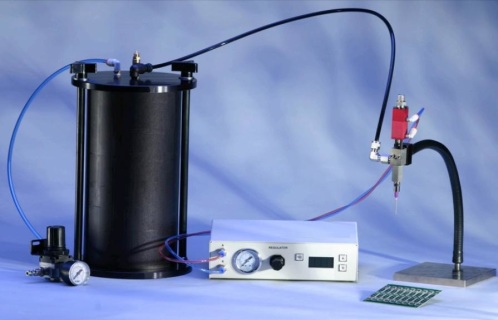

The 5101292-2LPKG includes the 5101292 Front Closing Valve the 7011010-2L - 2 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi.

This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for potting and encapsulation for electronics and medical device, Filling molds, timed dispensed shots filling vials or other receptacles, epoxy dispensing, flux, dam and fill, Paints and more. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility.

FULL SYSTEM PACKAGE

The 5101292-5LPKG includes the 5101292 Front Closing Valve the 7011010-5L - 5 liter open top reservoir, the 5900011VC valve controller and a desktop stand to hold the valve over the work area. Requires clean compressed air up to 100psi.

This system is intended for timed metered shots or manual user control, used in automation or at the desktop level for potting and encapsulation for electronics and medical device, Filling molds, timed dispensed shots filling vials or other receptacles, epoxy dispensing, flux, dam and fill, Paints and more. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps

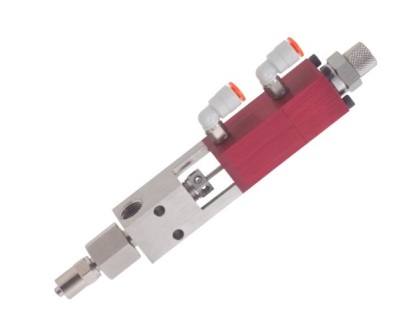

VALVE ONLY

The 5101292 = Front Closing Valve is intended to be used with any pressurized reservoir. Requires a valve controller that can provide air pressure to open and close. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: Depends on Reservoir, used for all viscosity 1 cps - Paste cps.

VALVE ONLY

The 5101293-HV = Front Closing Dispense Valve, High Flow is intended to be used with any pressurized reservoir. Requires a valve controller that can provide air pressure to open and close. These valves are steel and are not suggested for use with CA (Cyanoacrylate) material.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: Depends on Reservoir, used for all viscosity 1 cps - Paste cps.

Availability: Can range from 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. If you have never used this system, be sure to confirm compatibility.

RESERVOIR ONLY

The 7011010-2L = 2 Liter Reservoir, regulator & gauge, is intended to be used with any IDS Valve and most valves also require a valve controller.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps

RESERVOIR ONLY

The 7011010-5L = 5 Liter Reservoir, regulator & gauge, is intended to be used with any IDS Valve and most valves also require a valve controller.

REQUIRES A LINER - DO NOT DIRECT POUR. Most customers will use the bottle that the material comes in, set it directly inside, drop the feed tube in, and then pressurize.

Availability: From 2 - 4 week build time. Need multiple units? Contact IDS directly for a quote. Note: Know your material! Always confirm compatibility. Viscosity Range: 1 cps - 25,000 cps